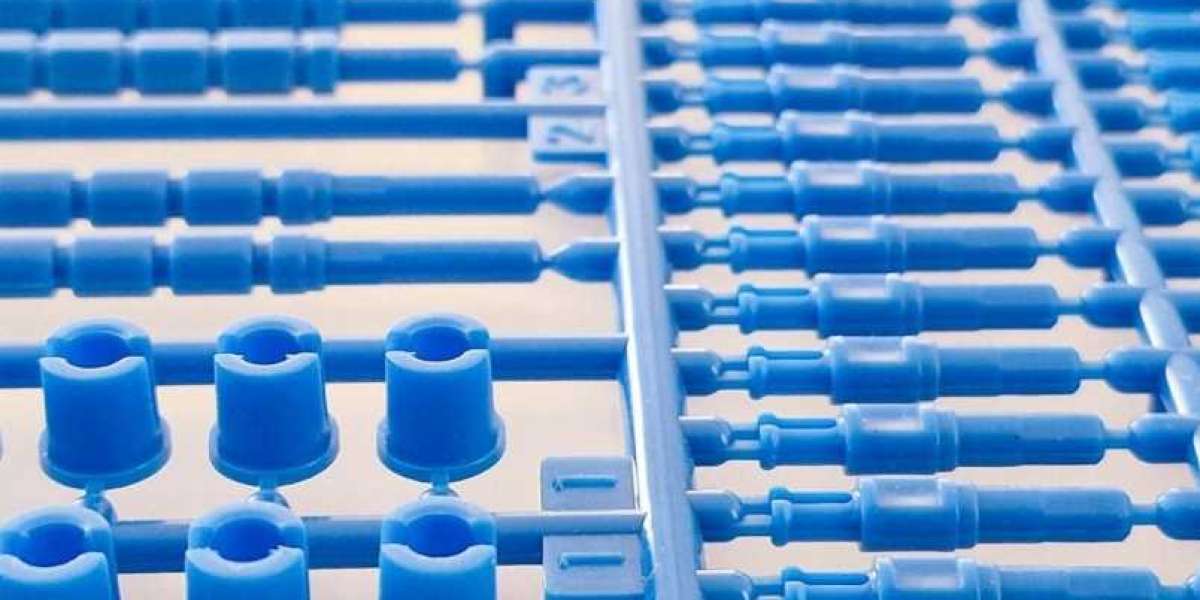

Wow, how time flies when you love what you do! When I was in college I never dreamed I’d have a job that I still liked after all these years. I still enjoy coming to work every day! Engineering failure analysis through forensic insights is invaluable for uncovering hidden issues within plastic injection molded products. By conducting forensic research, laboratory analysis can uncover resin issues leading to product failure. In addition to material assessments, mold inspections, process monitoring, defect analysis, and historical data reviews help manufacturers identify the causes of product failures and prevent them from recurring. In the dynamic field of plastic injection molding, engineering failure analysis through forensic research plays a critical role in ensuring the success of projects across diverse industries. We serve a wide range of industries who need to improve an existing product, transition a part from metal to plastic, or bring an entirely new product to market. If there is not enough injection pressure the plastic material will cool and solidify before the mold is properly packed.

A Foreman For An Injection-Molding Firm Admits That On

Depending on the type of resin used, mold temperature can impact properties, such as:Molded-in StressCreep ResistanceFatigue ResistanceWear ResistanceMolecular WeightDimensional StabilityMold Temperature IssuesMold Temperature is InconsistentMold Temperature Non-Uniform to Part Cavity ProximityExample of Mold Temperature Effects on a Part In plastic injection molding black specs and splay is usually caused by:Resin Contamination (non-compatible resins, dirt, etc.)Inadequate Resin Dry TimeImproper Melt TemperatureInjection Speed Too HighImproper Gate StyleU.S. Plastic Injection Molder Specializing in Engineering Resins We have been thriving in the plastic molding business for 45 years. We have the experience and certified in-house Master Molders, allowing us to take on projects of any complexity. PMC offers a comprehensive range of plastic molding services including mold design assistance, modeling, prototyping, manufacturing, and testing. Historical data can also shed critical insights into molding conditions and illuminate solutions to correct inconsistencies and/or inefficiencies.Molding Error Examples: Polyamides are commonly known as nylon. They are one of the most used engineering thermoplastics. Nylon is extensively used for wire coatings and other electrical components. Glass filled nylon is the preferred choice when you need a tougher material, as it makes the nylon considerably stronger.

How To Shape Plastic Without Injection Molding

Residence time is the amount of time the resin is exposed to heat in the barrel. If there is inadequate residence time the molecules will not absorb heat uniformly throughout the material. The under-heated material will become stiff and will cool before the mold is properly packed. This causes the molecules to shrink at different rates during the cooling process which results in mold warpage. Request a quote today for your next project.? Get a QuoteHave questions about our process? Working with PMC will get you the education skills you need to be a top performer, get pay raises, bonuses and promotions! We serve a wide range of industries requiring mission-critical parts, including aerospace defense, automotive, electronics, filtration and more. Plastic gears used to be found in very limited applications due to the uncertainty around their response to moisture, temperature, chemicals and certain other elements.